How is Xuan paper made?

Share

1. Preparation of core raw materials

-

Pteris serrata bark (core fiber source)

- Harvesting : Select 2-3 year old Phellodendron branches and cut them in winter to obtain the best fiber.

- Processing : After steaming and softening, peel and dry, soak in mountain spring water for several months to ferment naturally until the fibers become soft.

-

Shatin straw (supplementary material)

- Material selection : Only local rice straw from Jingxian County is used, the fibers are slender and flexible.

- Retting : After bundling, soak in lime water for 1-2 months to remove chlorophyll and impurities to make "straw blanks".

2. Raw material processing flow

-

Cooking and separation

- The bark of the golden sandalwood and the straw are steamed separately, and lime and soda ash are added to soften the fiber and sterilize it.

- After steaming, it is repeatedly beaten (the traditional process requires manual beating tens of thousands of times) to completely separate the fibers into pulp.

-

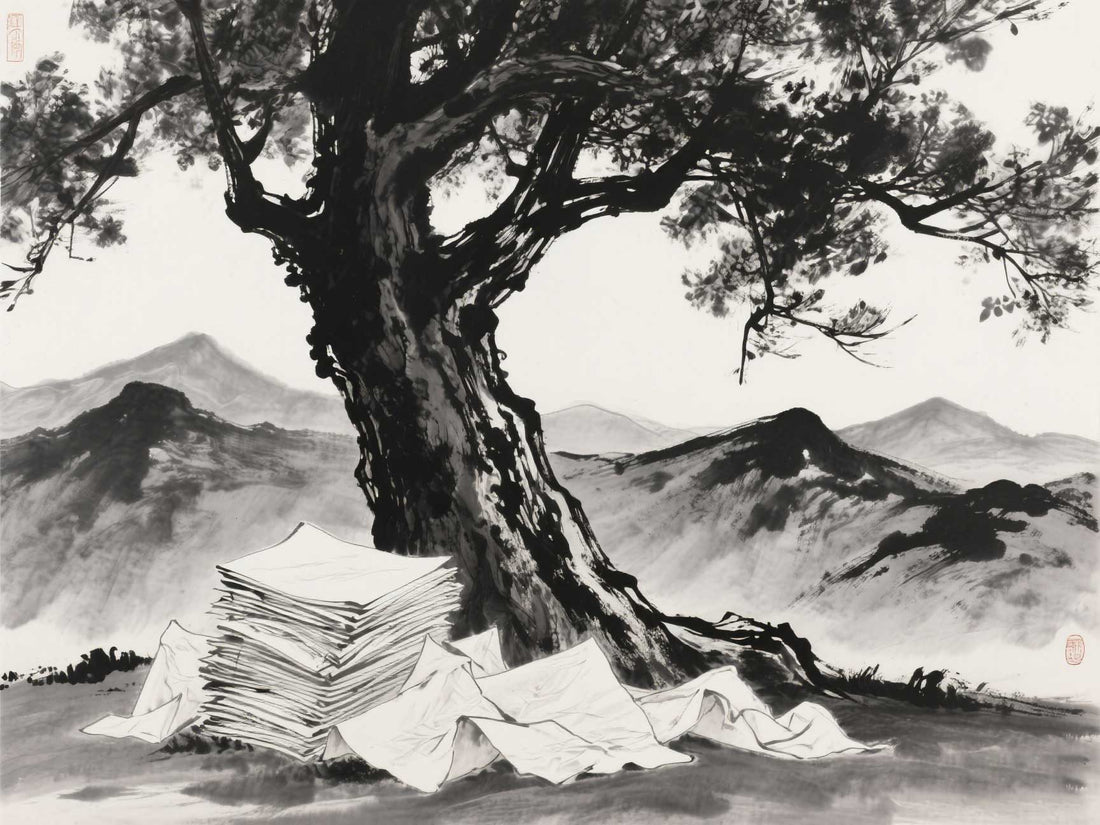

Bleaching process

- The pulp is spread on the hillside and naturally bleached by sunlight and rain for several months, forming white "Liaocao".

3. Papermaking

-

Paper scooping (key process)

- Two craftsmen work together to use a bamboo screen to evenly scoop fibers from the pulp trough to form wet paper sheets.

- The speed and strength of the action must be precisely controlled to ensure that the thickness of the paper is uniform.

-

Dehydration by stacking

- The wet paper sheets are stacked and pressed with heavy stones to remove excess water and increase the density of the paper.

4. Drying and post-processing

-

Paper drying

- The wet paper sheets are pasted on the drying wall, the surface is flattened with a pine brush, and the temperature is manually controlled to dry slowly.

-

Cutting and Inspection

- After drying, the pieces are cut into traditional sizes (such as four feet or six feet) and defective ones are manually removed.

Process characteristics and time consumption

- Complex process : From raw materials to finished products, it takes 108 processes and takes about 1 year .

- Uniqueness : Relying on Jingxian mountain spring water and traditional craftsmanship, its ink-absorbing properties and durability cannot be replaced by machine-made paper.

Core technology comparison

| Links | Traditional crafts | Modern improvements |

| Raw material handling | Natural fermentation, sun bleaching | Chemical bleaching (used by a few manufacturers) |

| Paper scoop tool | Handmade bamboo curtain | Mechanized papermaking (lower quality) |

| Drying method | Wall drying | Hot air drying (high efficiency) |